OIL MIST DETECTOR SCHALLER AUTOMATION

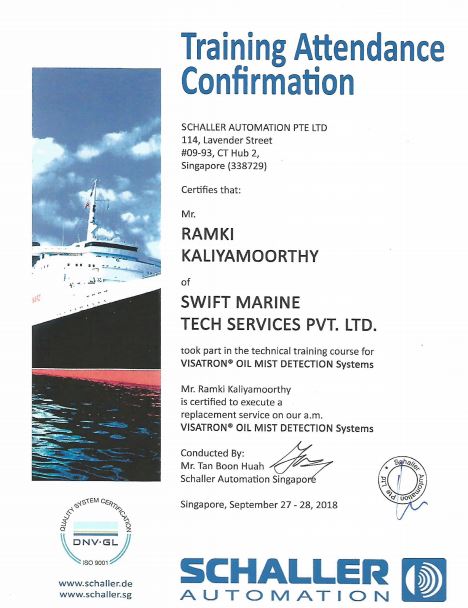

SMTS is your site authorized sales, service and support centre. Our site-trained technicians are available 24/7 for service, repair and regular maintenance to ensure the optimum operation of your Schaller Visatron OMD.

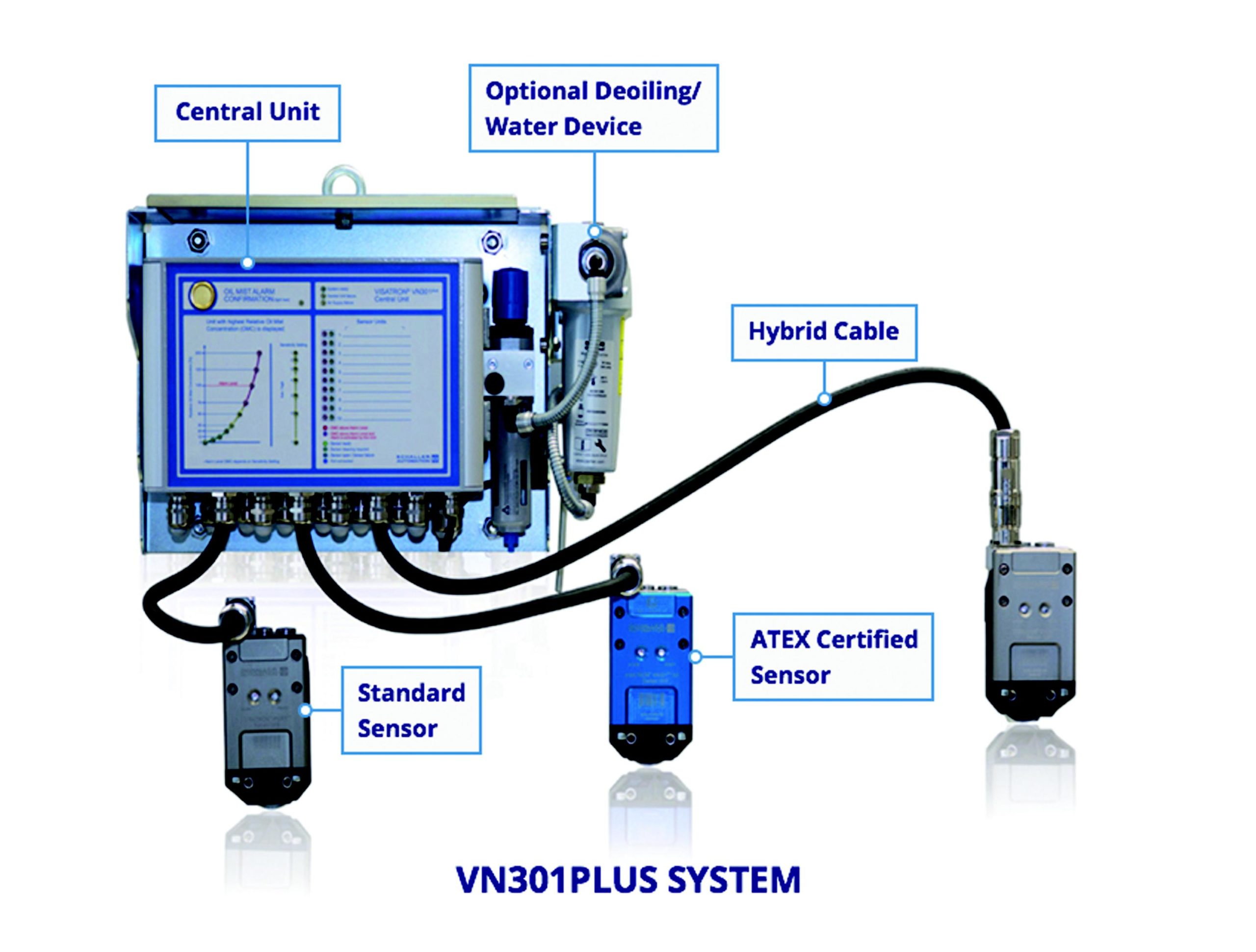

- Complete Systems

- System Installation

- Spare parts and Repair kits

Regular maintenance service is recommended to ensure the optimum operation of your equipment.

Contact our service department to discuss scheduled maintenance and to arrange your service.

Schaller Visatron Oil Mist Detectors

Routine maintenance should be performed yearly or every 6,000 running hours. Fresh air filters should be changed every 2 months, Pressure regulator filters should be changed every 6 months. Repair or exchange measuring head every 4 years.

Oil opacity measured by infrared optical light

Robust and fast-acting – seconds to engine shut down

Mandatory on engines over 2250KW or cylinder diameter of at least 300 mm.

Major class approvals: ABS, USCG, GL and more

Authorized installation and service by site trained technicians

CUSTOMISED OIL-MIST DETECTION SYSTEMS

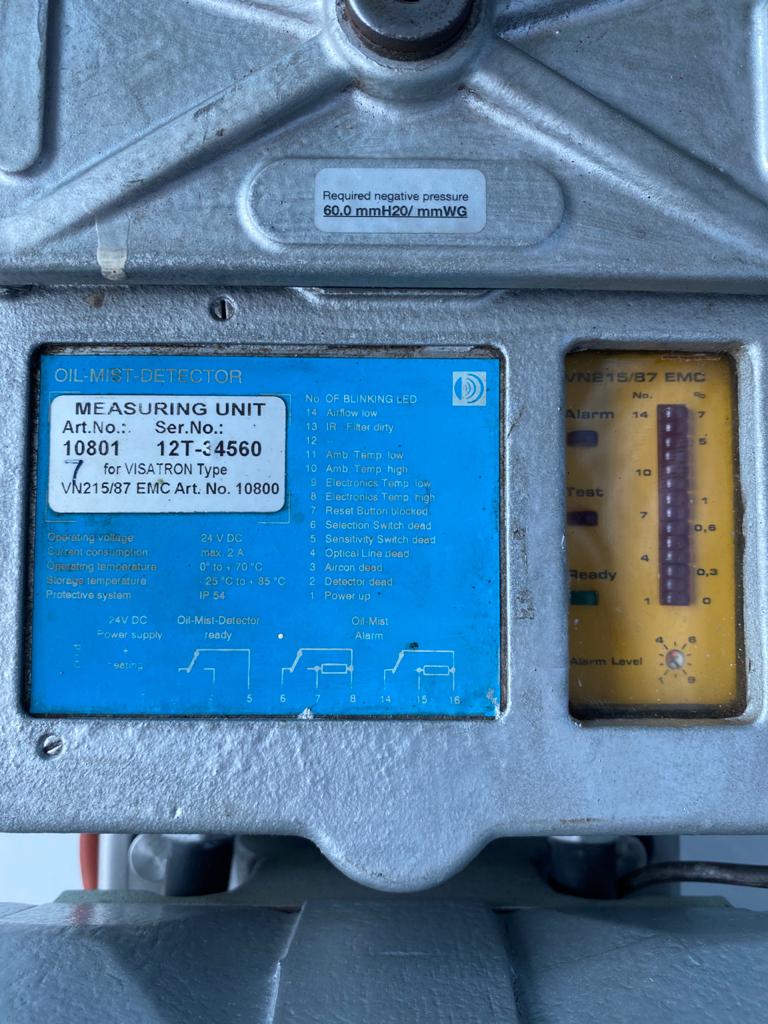

TESTED AND CERTIFIED UNIT

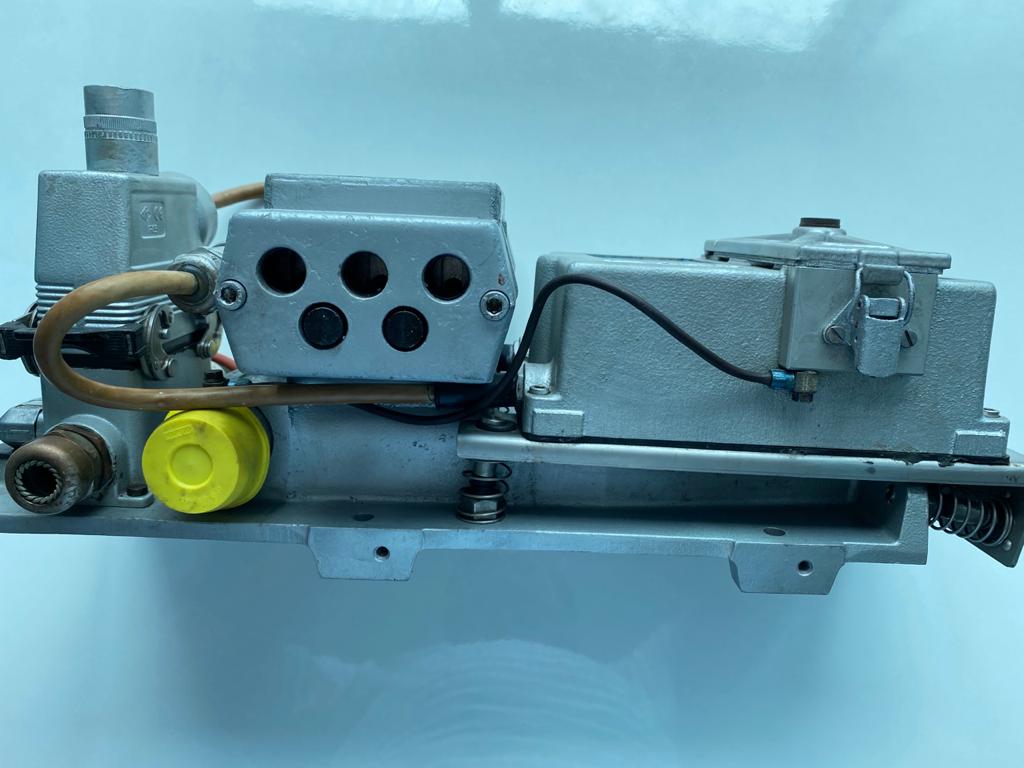

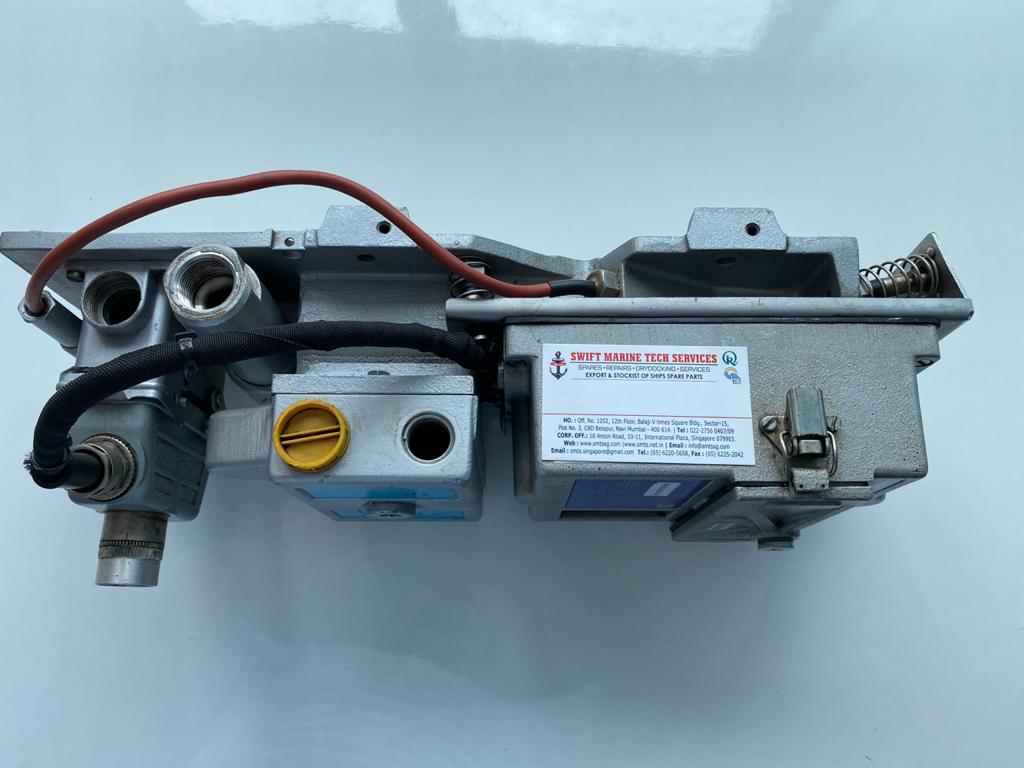

Schaller Tested & Certified Unit - VN 215/87 EMC - Complete Set

Schaller Tested & Certified Unit - VN 115/87 EMC - Complete Set

OIL MIST DETECTOR ADVANTAGES

Following the mandatory SOLAS regulations for fire precaution, classification societies to be the number one choice for oil mist detection systems to be the number one choice for monitoring as part of the safety system required for marine engines with power in access of 2,250kW, and / or a cylinder bore of more than 300mm. This is because generic sensors measuring temperature and pressure are not sufficiently effective to guarantee the required operating safety, as they do not monitor a number of lubricated sliding surfaces.

Surfaces that can generate intensive oil mist in addition to the crankshaft bearing system include:

- Pistons in cylinder liners

- Crankshaft bearings such as main bearings and big-end bearings

- Camshafts, their bearings and cams

- Timing gear shafts and their bearings

- Gear boxes with their bearings, and in some cases pumps

- Guide blocks and paths in cross-head engines