Description

PRINCIPLE

At high temperatures the oil used for lubricating engines generates vapours. When these come into contact with the colder atmosphere in the crankspace at temperatures around +70 deg. C, they condense into an oil mist and represent the condition associated with the excess temperatures such as those caused by main crankshaft, big end or connecting rod small end bearing defects.

” alt=”” aria-hidden=”true” />

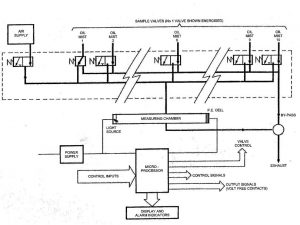

The Oil Mist Detector working on the principle that oil mist density is proportional to optical obscurity, samples the oil mist in the crankspace in a regular repetitive sequence. The sample is measured by passing it through a measuring chamber which has a light source at one end and a photo cell at the opposite end. The output signal from the photo-cell represents oil mist and is compared with threshold levels set during commissioning. If the thresholds are exceeded an alarm indicates the need for an engine slow-down and an immediate investigation of engine condition.

” alt=”” aria-hidden=”true” />

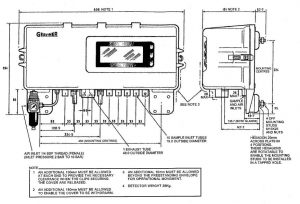

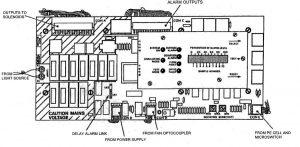

Oil Mist detection, now widely accepted as a means of providing early warning of incipient bearing failure in Diesel engines, advances into the era of the micro-chip with the Graviner Mark 5 Oil Mist Detector. The Mark 5 embodies electronic and electrical means of carrying out fast and accurate sampling of the crankspace oil mist. With the elimination of rotating mechanical parts in the Mark 5 and the introduction of micro-circuits, oil mist detection reaches a level which is the very best available using current technology

” alt=”” aria-hidden=”true” />

Our company has a specialized techical team for repairing Graviner OMD’s and after several tests we sell the reconditioned products with 1 year guarrantee.